Production Process

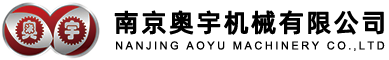

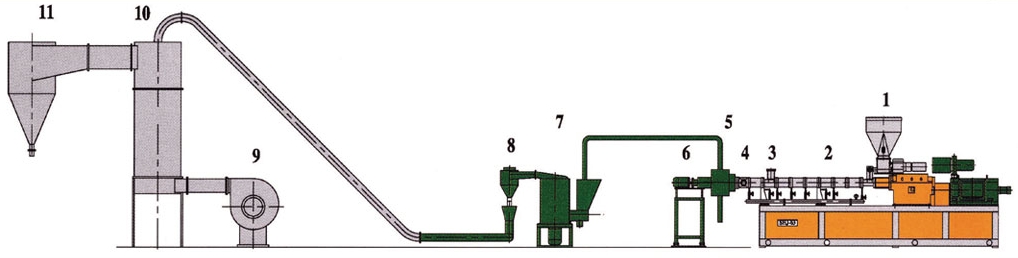

Strand pelletzing sets

Applicable to: reinforced plastics, inorganic fillings, various cable materials, masterbatches, and insulating cable materials.

1. Metering feeder 2. Twin screw extruder 3. Exhaust chamber 4. Manual or hydraulic screen changer 5. Cold cutting head 6. Cooling water tank 7. Blow dryer 8. Pelletizer

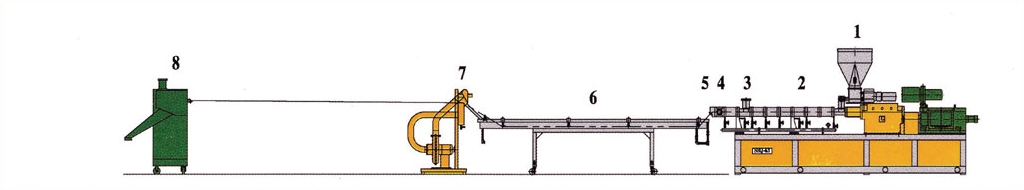

Air-cooling pelletizing sets

Applicable to: high-filling masterbatch, XLPE cross-linked cable material, PVC cable material, shoe sole material, TPR thermoplastic elastomer

1. Metering feeder 2. Twin screw extruder 3. Exhaust chamber 4. Manual or hydraulic screen changer 5. Hot cutting die 6. Cold air pelletizer 7. Conveying fan 8. First cyclone separation 9. Second cyclone separation

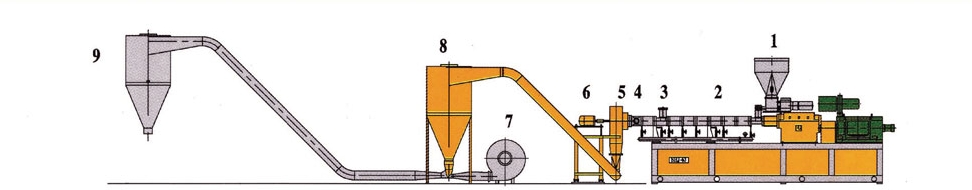

Water-ring pelletizing set

Suitable for: various cable materials, EVA thermoplastic materials, various color masterbatch, low filling masterbatch, TPU, TPR thermoplastic elastomers

1. Metering feeder 2. Twin screw extruder 3. Exhaust chamber 4. Manual or hydraulic screen changer 5. Hot cutting die 6. Water ring pelletizer 7. Centrifugal dehydrator 8. Collection bin 9. Drying fan 10. Fluidized bed 11. Storage bin

Under-water pelletizing set

Suitable for large equipment such as adhesive particles, thermoplastic elastomers, processing PE, PP, ABS, PS, etc

1. Metering feeder 2. Twin screw extruder 3. Exhaust chamber 4. Manual or hydraulic screen changer 5. Hot cutting die 6. Water ring pelletizer 7. Centrifugal dehydrator 8. Collection bin 9. Drying fan 10. Fluidized bed 11. Storage bin

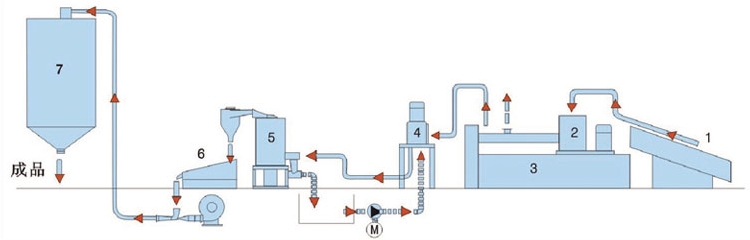

Single Screw Pelletizing Line for Film Reclamation

1. Belt feeder 2. Film crusher 3. Single screw exhaust extruder 4. Vertical water ring pelletizer 5. Centrifugal dehydrator 6. Vibrating screen 7. Finished product silo

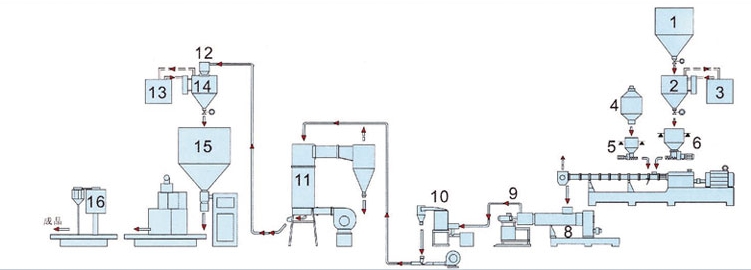

Whole Set Production Line for Silance-Crosslinked Cable and Pipe Compounds

1. Raw material warehouse 2. Drying hopper 3. Molecular sieve dryer 4. Raw material tank 5. Loss-in-weight metering pump 6. Loss-in-weight electronic scale 7. Twin screw main engine 8. Single screw main engine 9. Water ring pelletizer 10. Centrifugal dehydrator 11. Fluidized bed 12. Vacuum feeder 13. Molecular sieve dryer 14. Drying hopper 15. Finished product warehouse 16. Vacuum packaging machine