2024-10-29

Four differences between twin-screw extrusion testing machines and single-screw extruders

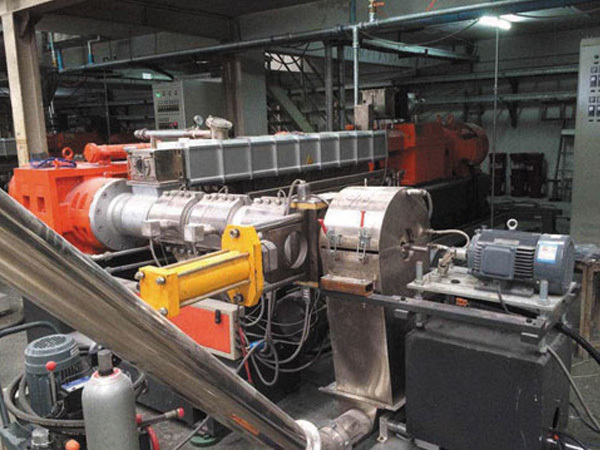

The twin-screw extrusion testing machine is a commonly used mechanical equipment in industrial processing. It is generally used for the plasticization processing of some materials. In many fields, it plays an important role. In fact, in addition to the twin-screw extrusion testing machine, the single-screw extruder is also a commonly used equipment in industrial production.

2024-10-29

Working principle and selection points of SHJ series twin-screw extruder

When choosing an SHJ series twin-screw extruder, you should pay attention to whether the composition of each part is scientific and reasonable and whether the outer surface of the twin-screw extruder is finely made. From many aspects, we can see whether the technical situation and comprehensive strength of plastic extruder manufacturers can meet the requirements for providing services for our subsequent production.

2024-10-29

What are the components of the underwater pelletizing unit and its advantages?

The underwater pelletizing unit generally uses an extruder of TPE/TPR and other materials to draw the strips. After cold cutting in the water tank, the pelletizing work is usually processed into cylindrical particles, which are cut while extruding. It can also perform cooling work, which is very convenient and practical.

2024-10-29

The twin-screw extruder barrel is an important part of the extruder in the extrusion compression molding system. The barrel and the screw work together, the barrel contains the screw, and the screw rotates in the barrel.

2024-10-29

With the increasing awareness of environmental protection and the pursuit of sustainable utilization of resources, green and efficient production methods have attracted more and more attention from enterprises.

2024-10-29

Twin-screw extruder calculation method and introduction to various aspects of performance

Twin-screw extruder screw diameter Screw diameter refers to the outer diameter of the screw, represented by D, in mm. Like the single-screw extruder, the screw diameter of the twin-screw extruder is an important technical parameter. Its size indicates the production capacity of the twin-screw extruder to a certain extent.

2024-10-29

The twin screws of the extruder can be divided into three sections functionally.

The way the twin-screw extruder is used is to force feed according to the gap between the two screws of the twin-screw extruder. The difference between it and the single-screw extruder is the friction drag between them for solid transportation.

2024-10-29

When a co-rotating parallel twin-screw extruder fails, these methods can be used to deal with it.

The co-rotating parallel twin-screw extruder is a piece of equipment widely used in the plastic processing industry. It uses two co-rotating screws to heat and melt the plastic material, and then extrude it through the mold.

2024-10-29

The mystery and application of twin-screw extruder barrel

In the field of polymer material processing, a twin-screw extruder is a piece of equipment. It plasticizes, mixes and homogenizes materials through two intermeshing screws. It is widely used in plastic modification

2024-10-29

Single-screw extruder unit - an efficient assistant for modern plastic processing

In modern society, with the continuous advancement and innovation of science and technology, various advanced equipment and technologies continue to emerge. Among them, the single-screw extruder, as an efficient and precise plastic processing equipment, has become an important means for many companies to pursue production efficiency and product quality.