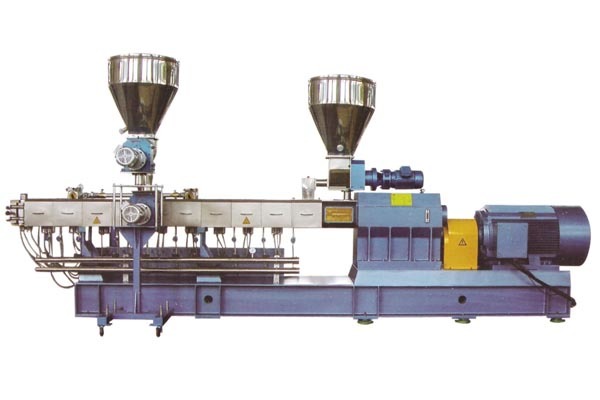

Technical features of parallel co-rotating twin-screw mixing extrusion/granulation unit

2019-01-08

◆The screws of the main machine rotate in the same direction and are designed using the building block principle. It has excellent dispersion and mixing performance, controllable material residence time, good exhaust devolatilization performance, excellent interchangeability, self-cleaning, and flexible modularization Combination and other characteristics achieve a wide range of multi-functions, multi-purposes and special requirements for specific requirements.

◆Serialization of host specifications: screw diameter ¢20mm- ¢200mm, and divided into four sub-series A, B, C and D according to different speeds and torque levels, providing users with more choices.

◆Plasticizing and mixing screw

The screw element is fully meshed and conjugate designed, with excellent self-cleaning and random interchangeability;

The screw element and the mandrel are connected in the form of advanced involute splines to achieve higher working torque and larger screw working volume; more than 20 years of rich experience in screw configuration design and software technology have continuously introduced new screw elements and Combined configuration to meet the process requirements of various material processing.

◆Transmission system

Integrated deceleration and torque distribution, new structural design, enhanced safety margin, high-precision hard tooth surface grinding, key bearings and seals are all imported, equipped with independent forced lubrication cooling system; optional original imported high-speed The torque transmission box and safety torque protector further improve the performance of the equipment.

Previous:

Next: