Features

▪ The main electrical control components are Siemens products

▪ The control buttons are made by French Schneider

▪ The AC motor of the host speed control device is a Japanese variable frequency speed regulator, and the DC motor is a digital speed regulator of the British Continental Company.

▪ The speed control device of the feeder is a Japanese frequency converter.

▪ The temperature control instrument adopts the product of Japanese RKC company, dual-channel intelligent type, one temperature control in each zone

▪ The pressure gauge range is 0~25Mpa

▪ The solenoid valve adopts solenoid valve CEME9313 imported from Italy.

▪ Heating is controlled by a temperature controller through a solid-state relay, using high-temperature resistant wires

▪ Electrical control cabinet control includes: temperature control system, drive system, interlocking control system

▪ Chain control system

The lubrication system is interlocked with the main engine, that is, the main engine can be started only after the oil pump is started; the feeding system is interlocked with the main engine, that is, the feeder can be started only after the main engine is started; the pressure system is interlocked with the main engine, that is, when there is overpressure, both the main engine and the feeding Stop working; the current is interlocked with the host, that is, when there is an overcurrent, the host and the feeder stop working.

▪ In addition to the conventional instrument mode, it can also provide analog operation panels, PLC systems, PCC systems or large computer workstation control systems, etc.

Keywords: single screw granulator twin screw granulator underwater granulator

Electrical instrument control cabinet

Contact Us

Classification:

Related Products

Electronic control system, melt pump system, non-stop screen changer, start-up valve device, mouldboard head device, pelletising trolley device, bypass piping device, hydraulic control system centrifugal dewatering system

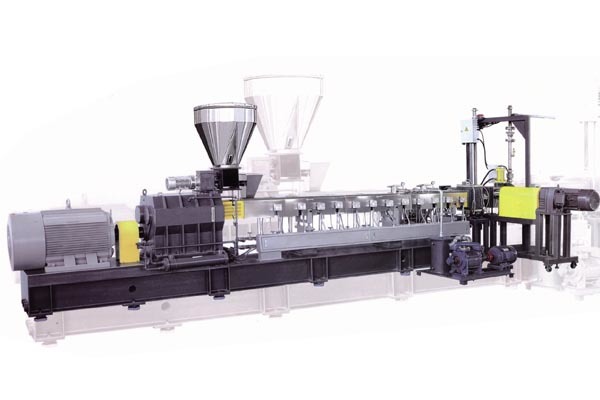

The connection between the host screw components and the core shaft adopts an involute spline form synchronized with international standards, fully tapping into the potential of limited structural space while achieving higher working torque and larger screw working volume.

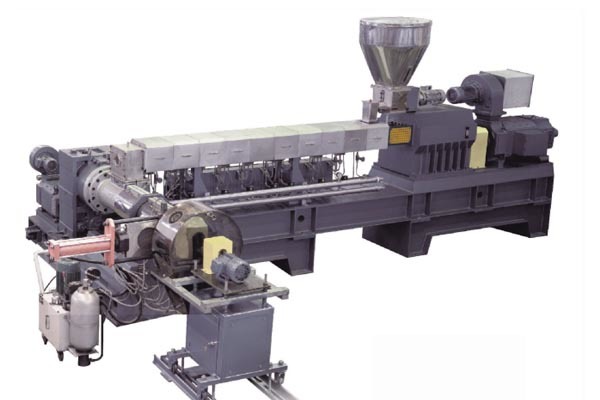

The first stage is CM type high-speed isotropic twin-screw mixer, the second stage is CM series low-speed single-screw extruder, both of them are arranged vertically and orthogonally, constituting a double-stage composite unit.

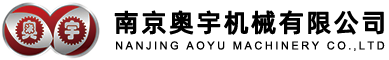

Parallel co-rotating twin-screw mixing extrusion/granulation unit

The screw of the main machine rotates in the same direction and adopts the block-type principle design, which has excellent dispersing and mixing performance, controllable material residence time, good exhaust and de-volatilisation performance, excellent interchangeability, self-cleaning, flexible modular combination and other characteristics, realising a wide range of multifunctionality, multi-purpose and unity of specific requirements.