Characteristics

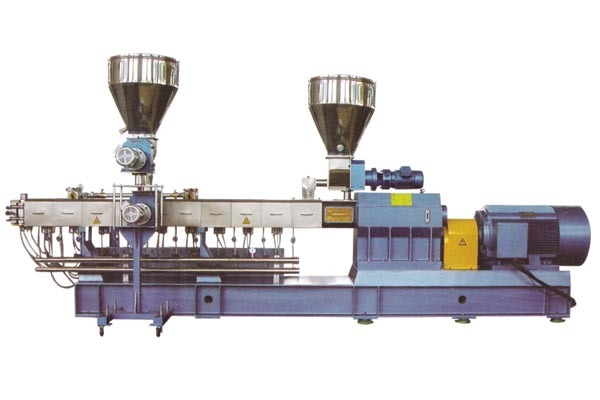

The screw element of the mainframe adopts the involute spline form synchronised with the international level for its connection with the core shaft, which fully exploits the potential of the limited structural space and achieves higher working torque and larger working volume of the screw.

Depending on the different material process and application requirements, on the basis of conventional A series (n<500r/min, T/A3<6) and high speed B series (n>600r/min, T/A3<6) products, we have recently launched high-torque C series (n<500r/min, T/A3>8) and high speed torque D series (n600r/min, T/A3>8) products, which are suitable for all levels of users.

These products provide a wider range of choices for all levels of users.

New torque distribution transmission device, strengthened design safety margins, high-precision hardened gear grinding, key bearings are imported, Runner series interlocking protection, the pursuit of higher reliability.

Various special pelleting systems, water-cooled pull-strip pelleting, cold-air pull-strip pelleting, air-cooled die face hot pelleting, eccentric water-mist hot pelleting, and underwater die face hot pelleting, etc., are recommended according to the needs.

The important components of the electric instrument and automatic control system are all imported, in addition to the conventional instrument mode, we can provide analogue operation panel, PLC system or large computer workstation control system.

Low vibration, low noise, the whole machine can be installed without foundation, can be placed on the level ground, reducing the requirements for the site and installation, more convenient to use.

Keywords: single screw granulator twin screw granulator underwater granulator

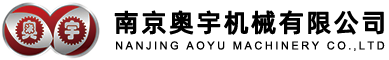

SHJ twin-screw extruder unit

Contact Us

Classification:

Related Products

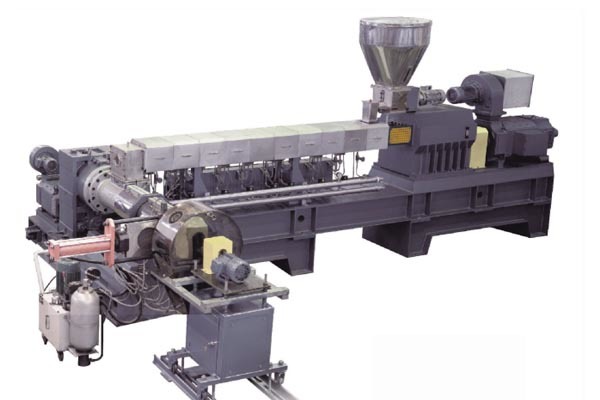

Electronic control system, melt pump system, non-stop screen changer, start-up valve device, mouldboard head device, pelletising trolley device, bypass piping device, hydraulic control system centrifugal dewatering system

The connection between the host screw components and the core shaft adopts an involute spline form synchronized with international standards, fully tapping into the potential of limited structural space while achieving higher working torque and larger screw working volume.

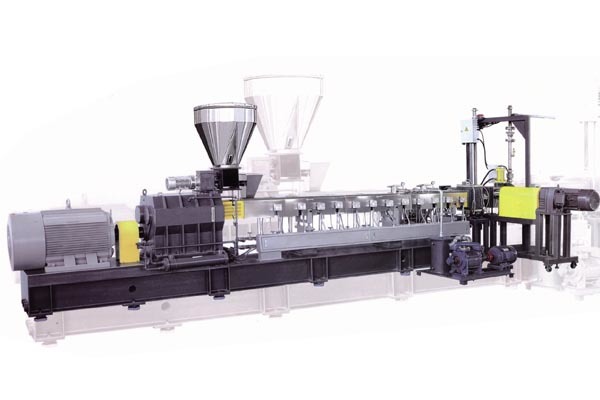

The first stage is CM type high-speed isotropic twin-screw mixer, the second stage is CM series low-speed single-screw extruder, both of them are arranged vertically and orthogonally, constituting a double-stage composite unit.

Parallel co-rotating twin-screw mixing extrusion/granulation unit

The screw of the main machine rotates in the same direction and adopts the block-type principle design, which has excellent dispersing and mixing performance, controllable material residence time, good exhaust and de-volatilisation performance, excellent interchangeability, self-cleaning, flexible modular combination and other characteristics, realising a wide range of multifunctionality, multi-purpose and unity of specific requirements.